building your own trickkite

Fabrics |

|

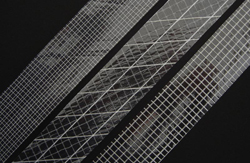

Icarex: Produced in Japan by Teijin. This fabric is made of polyester with a low weight (about 31 grams), high strength and low stretch as advantages. On top of that, Icarex is water repellent (also a positive side of polyester) and very good airtight. The tear-resistance of Icarex is less than can be found in a lot of spinnaker fabrics that are made of nylon. Mostly used with trick kites and single-line kites. The UV-resistance of Icarex is better than that of Chikara, so the colours of Icarex last longer (retain their beauty). |

Chikara: Probably the most used material in kite building. For trick kites however, the amount used is less. The fabric is made of nylon and double sided coated, so it is very good water repellent. It is very strong and doesn't tear easily at a relative low weight (about 41 grams). The fabric feels soft and the square structure is very visible (5 x 5 mm). Airtight and can be found in many colours. |

Rip stop: This is a small ribbon of Chikara mainly used to make the trailing edge. For SUL and Indoor models we can also use this for the Leading Edges

|

Dacron: Is a synthetic polyethyleen terephthalate (PET) fiber and is the woven fabric version of Mylar. These small ribbons are used to make the leading edges. Dacron is very strong and flexible, has less stretch than nylon and is very water repellent. Less favorable is the durability. The UV-resistance of Dacron may lessen after a while. |

Mylar: This fabric is made by melting polyester. The slightly transparent foil is coated with fortification threads and a damped layer of aluminium, making the fabric absolutely unstretchable. The light version of Mylar is used for light kites such as the indoor model. The heavier version is used to fortify the kite on targeted places. |

Velcro: You can buy this in any confection store, it is used to tension the spine and hold it in place. You can also use it as fortification behind the top spreader to protect the fabric against the spine |

| Back |